DESIGN

Innovation and creativity converge with value engineering in our design team where product development and prototyping happen as a seamless process to galvanize mind to market time frames for CLIENTS. New original designs are a key differentiating factor. The company has historically evolved around its strengths in design in modular office furniture. Increasingly, the company sees itself growing with design capability and design sensitivity as its core for clients only.

BUILD

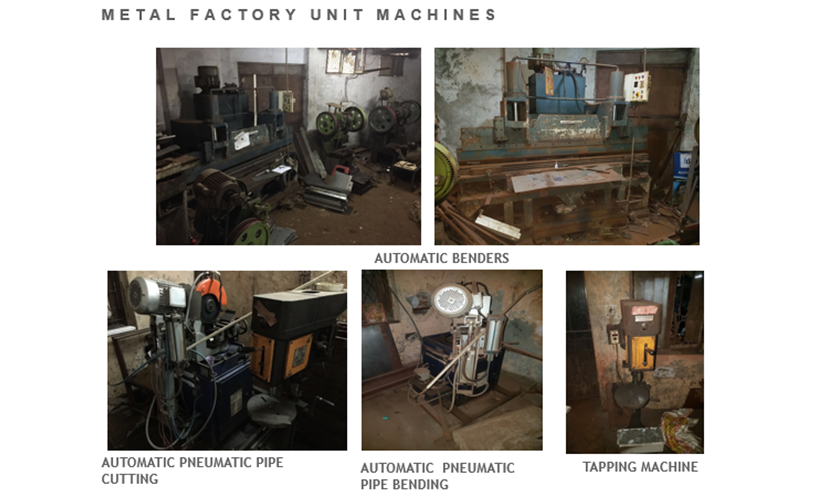

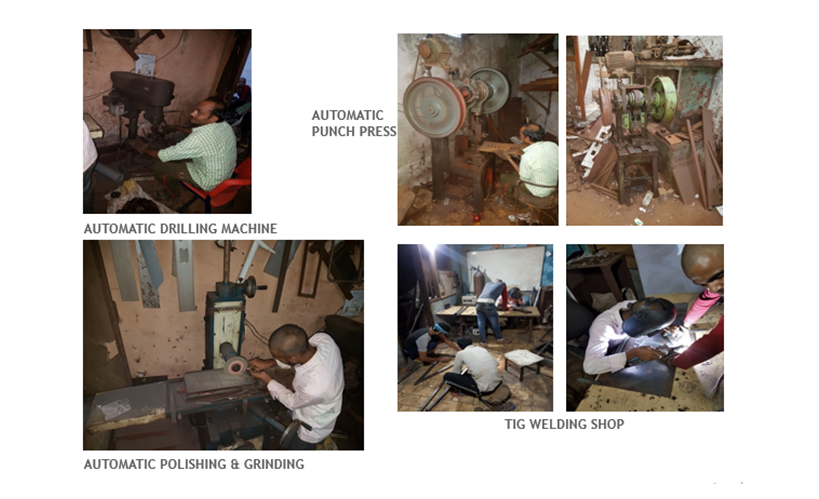

A combination of factory machineries and composite technologies along with a tradition of skilled labourers in our factory enables us to build high volumes of office as well as institutional spaces with consistent quality. Over the years, the company has gained experience in managing an end-to-end solution for its large customers in modular office furniture segment. We are able to understand customer requirements, manufacture the required product through our internal production facility and in the process ensuring quality for the end customer.

DELIVER

A country wide network of installation teams and logistic providers’ helps in providing rapid installation at multiple sites simultaneously both for Office and Institutional clients alike.

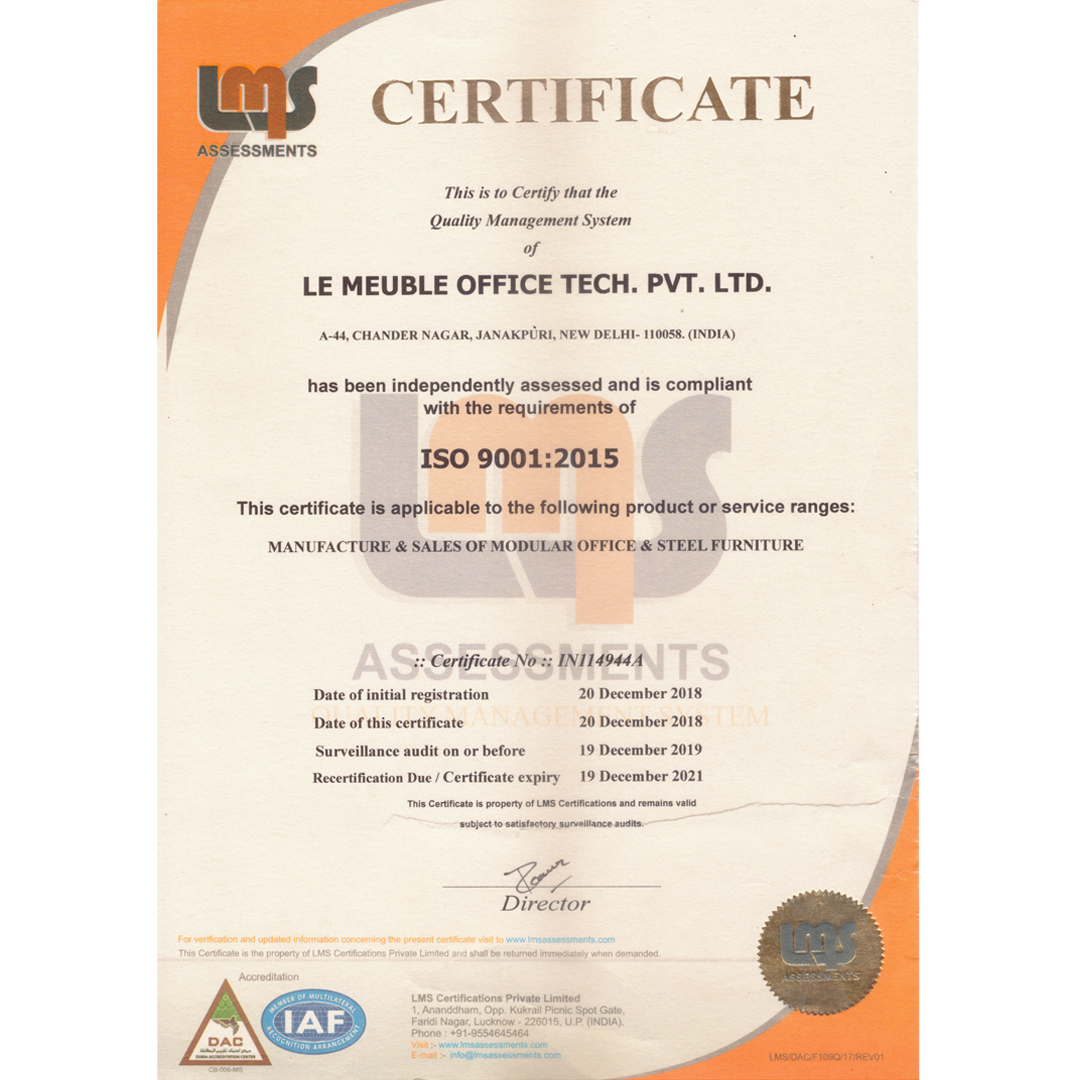

We have International Certifications as mentioned below:

ISO 9001 : 2008

ISO 14001 : 2004

OHSAS 18001 : 2007

We source our raw material from best of the suppliers spread across country. We are a project oriented company and have expertise to execute large projects with precision. Our range of products covers Office furniture like workstations, cabin tables, meeting tables, café tables, chairs, storages, Educational furniture like classroom furniture, library furniture and Laboratory furniture.

Please find below the list of Plant & Machinery details which we have in our factory.

LIST OF MACHINERIES IN METAL & POWDER COATING UNIT:

LIST OF MACHINERIES IN WOODEN UNIT: